Hydraulic Cylinder Basic Structure

he primary function of a hydraulic cylinder is to convert hydraulic or pneumatic energy into mechanical motion, enabling linear or oscillating movements in machinery. Hydraulic cylinders, which utilize liquid hydraulic fluid to transfer energy, are also known as oil cylinders or hydraulic cylinders. Those that use compressed air to convert energy are referred to as air cylinders or pneumatic cylinders.

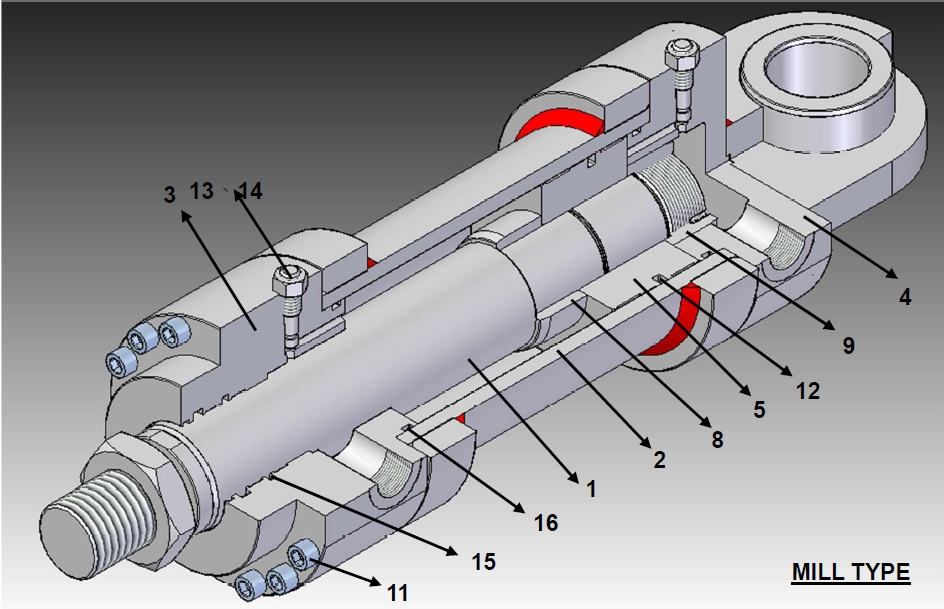

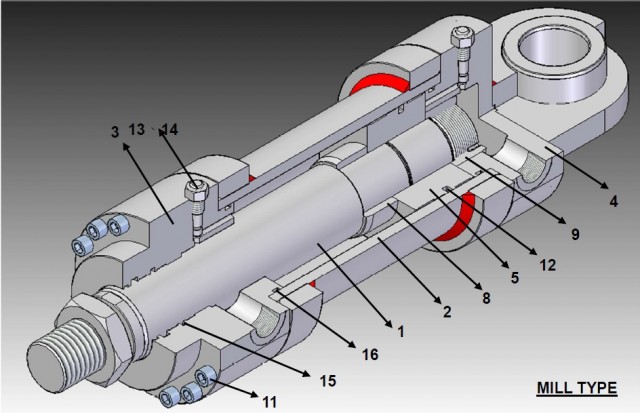

The basic structure includes the following components:

- Piston Rod (ROD)

- Cylinder Tube (TUBE)

- Head Cover (RC)

- Bottom Cover (HC)

- Piston (PISTON)

- Retainer (RET)

- Guide Bush (BUSH)

- Cushion Ring (CUSHION)

- Rear Cushion Ring

- Bolt (Nut)

- Piston Seal (Piston Seal)

- Cushion Valve, Check Valve (Cushion Valve, Check Valve)

- Air Vent Valve (Air Vent)

- Rod Seal (Rod Seal)

- O-Ring (O-Ring)

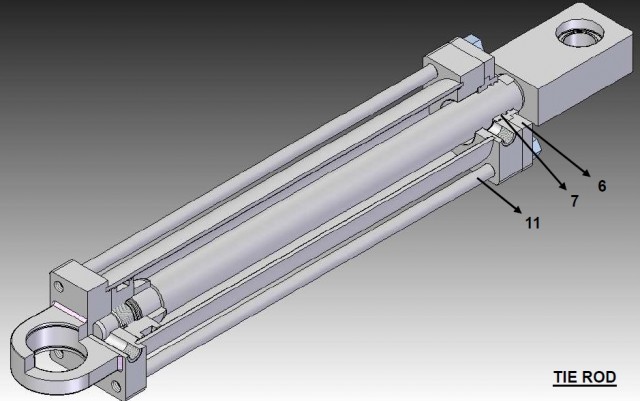

Additionally, the cylinder can be classified as Mill Type or Tie Rod based on the bolt fixation method.

Please refer to the attached diagram for details.

Company

Hopetech’s complete production system constitutes of planning, design, manufacturing and strict quality control. We thank many of our customers who are listed companies and have adopted our hydraulic/pneumatic cylinders so that we are able to maintain high and stable quality of our products and build exellent reputation for Hopetech.

News Categories